NCKU Gallium Bonding team, a new force in electronic components joining

With the rapid development of electric vehicles and high-power electronic components, the technology of joining parts to parts must also keep pace with the times. At present, the mainstream bonding material for high power electronic components on the market is silver paste. In view of the high cost of commercially available silver paste and the harsh environment in which it is used, Professor Lin Shih-Kang of the Department of Materials Science and Engineering at National Cheng Kung University (NCKU) led his laboratory team to create "Gallium Bonding," which replaces silver paste with gallium-based paste for joining to achieve not only lower costs but also better electrical and mechanical properties.

According to the “Gallium Bonding” team, the technology is focused on the use of temporary liquid joining techniques to produce a new type of paste based on the metal element Gallium in place of the current expensive silver-based paste, while the gallium paste offers advantages such as reduced process environmental conditions, extended joint life and high thermal conductivity.

Due to the low melting point of gallium metal, a bond can be made between the metal parts to be joined by applying gallium paste and pressing it tightly, at relatively low temperature and pressure, without creating a structurally weak compound, and can result in a bond structure with high structural strength and other characteristics.

The team said that with the NCKU Dreams Come True project grant, it can clearly understand the preparations to be made when transforming laboratory results into commercial products, such as how to protect patents when transferring technology, or the personnel costs and job planning required when setting up a company at the commercial stage, in addition to the planning of the use of funds in stages, which can speed up the process of commercializing laboratory products.

For future development, the team has set short-, medium- and long-term goals such as completing the testing of products for practical applications, improving the technological readiness and validating it in the real world, and commercializing all viable proprietary materials in the laboratory to become a proprietary material technology.

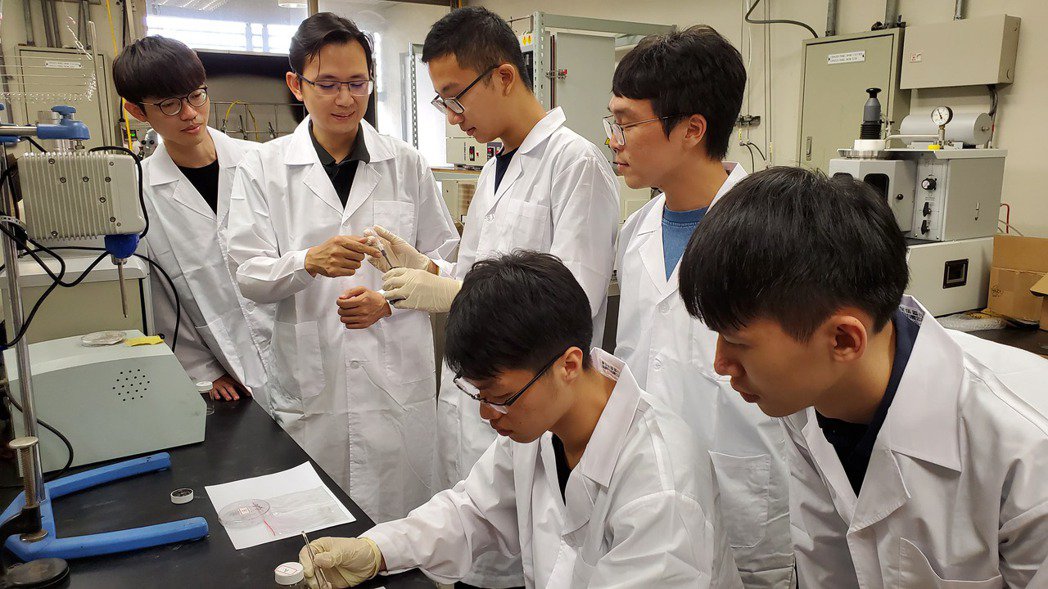

Professor Lin Shih-kang of NCKU's Department of Materials Science and Engineering led his laboratory team to develop the use of gallium-based paste instead of silver paste for bonding, which not only reduces costs but also achieves better electrical and mechanical properties. Photo by Chang Chieh

Prof. Lin Shih-kang (center) of the NCKU Department of Materials Science and Engineering poses for a group photo with the Gallium Bonding lab team. Photo by Chang Chieh